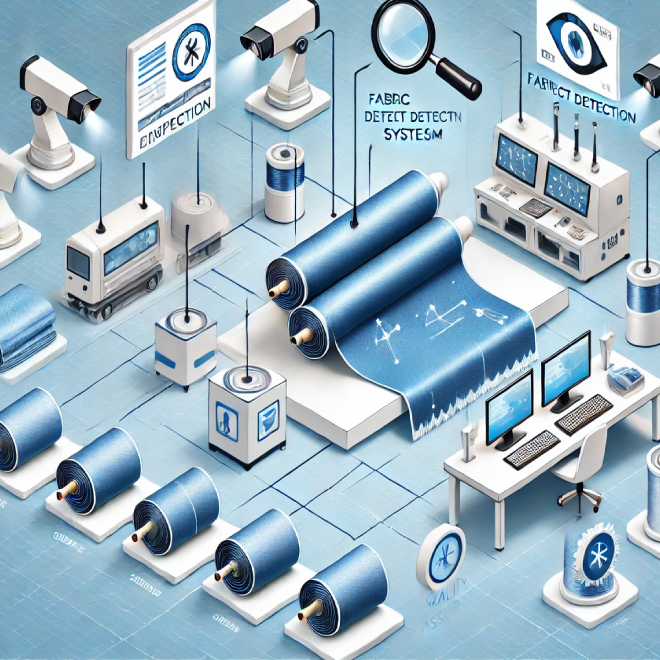

Advanced Fabric Defect Detection System is transforming quality control in textile manufacturing. This system uses AI-powered algorithms to detect even the most minute flaws, lowering the danger of defective products reaching the market.

Advanced Fabric Defect Detection System is transforming quality control in textile manufacturing. This system uses AI-powered algorithms to detect even the most minute flaws, lowering the danger of defective products reaching the market.

By automating fault detection, manufacturers can achieve flaw identification accuracy of up to 98%. It improves production efficiency by 30% while reducing material waste. Real-time monitoring assures consistent quality across all batches.

Implementing this technology can result in significant cost savings and improved brand reputation for textile enterprises.

Automating fault detection reduces manual inspection time, allowing producers to spot problems sooner. This increases overall production speed by up to 30%, allowing firms to increase output while maintaining quality.

Minimizing material waste and rework can dramatically reduce production costs. This results in more efficient resource utilization and increased profitability, making the business more cost-effective in the long run.

Real-time monitoring guarantees that each cloth batch retains its excellent quality. It aids in the early detection of flaws, preventing them from slipping through and maintaining uniformity in finished products.

Immediate problem detection allows for immediate modifications, decreasing production delays and downtime, hence keeping the manufacturing process operating smoothly.

By regularly producing defect-free fabrics, businesses gain customer trust and improve their brand reputation, resulting in increased customer loyalty and stronger market positioning.

System works by examining each fabric in real time, looking for flaws or anomalies during the manufacturing process.

Processing and machine learning, the system detects even the smallest errors, ensuring that no mistakes go undiscovered.

The system classifies and records the problems for later inspection, allowing for speedy identification of likely causes.

With existing production lines, needing minimal intervention. Continuous monitoring assures high-quality fabric throughout the manufacturing process, allowing manufacturers to maintain control over each batch and achieve consistent results

Our system uses cutting-edge AI algorithms that constantly learn and adapt, enhancing flaw detection accuracy with each use.

It scans fabric in real time, enabling for the prompt detection of flaws during manufacturing, reducing delays and assuring uniform quality.

The system is very flexible, allowing you to tailor it to identify a wide range of fabric faults based on your individual manufacturing requirements.

Our system is designed to interface seamlessly with existing production lines, requiring little setup and running smoothly without affecting workflow.

The system creates extensive reports that categorize faults, allowing producers to see patterns and make informed decisions to improve operations.

Using an intuitive and simple interface, operators can easily monitor fabric quality and obtain critical data without requiring technical knowledge.

A fabric defect detection system is a cutting-edge technology that employs artificial intelligence and machine learning to automatically detect flaws in fabrics throughout the production process. It serves as a cloth defect checker, assisting producers in detecting problems such as holes, stains, and irregular textures in real time, ensuring the manufacturing of high-quality fabrics.